Foundry Model Making with Sträfor by Evomatec – Precision, Lightness, and Quality for the Heat Treatment of Castings

Innovation in Foundry Model Construction and Thermal Processing

Foundry model making with Sträfor (Expanded Polystyrene) by Evomatec represents a new generation of high-precision, lightweight, and dimensionally stable models specifically developed for the precise casting of industrial components.

Combined with advanced heat treatment technology, Evomatec offers tailored solutions that cover the entire process — from model design to microstructure optimization of every casting.

Through precise CNC machining, digital mold simulation, and controlled thermal management during heat treatment, Evomatec achieves casting quality that meets the highest industrial standards — trusted by sectors such as mechanical engineering, automotive manufacturing, and energy technology.

Innovation in Foundry Model Making – Sträfor as a High-Performance Material

Sträfor, a special rigid foam based on polystyrene, has become an increasingly popular and intelligent model material in foundry model making.

Its key advantages lie in the combination of shape stability, machinability, and thermal resistance, making it ideal for models used in sand casting and investment casting processes.

Advantages of Evomatec’s Sträfor Foundry Model Making:

-

Lightweight structure with high dimensional stability

-

Easy CNC and 5-axis machining capability

-

No warping or cracking under thermal load

-

High accuracy and fine surface structure

-

Resistance to molding compounds and binders

Evomatec combines Sträfor models with innovative annealing technologies, ensuring thermal synchronization throughout the casting process for maximum precision.

Industrial Precision – From Model Design to Heat Treatment

The ultimate goal of every casting process is a dimensionally stable, stress-free, and homogeneous casting.

Achieving this requires complete harmony between every production stage — from model construction to mold making and heat treatment.

Evomatec provides integrated solutions that merge foundry model making, foundry technology, and heat treatment of castings into one unified system.

Main Advantages:

-

Reduction of internal stresses through stress relief annealing

-

Grain structure stabilization through normalization of cast iron

-

Increased strength through tempering of steel castings

-

Improved elasticity through targeted tempering processes

-

Precise temperature control during thermal treatment for consistent results

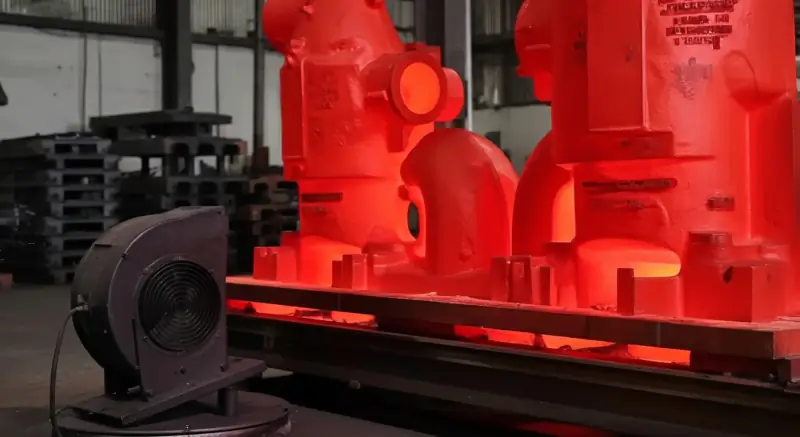

Heat Treatment of Castings – The Key to Superior Casting Quality

Heat treatment determines the mechanical performance and service life of any casting.

During the casting process, stresses, porosity, and microcracks can develop — these are eliminated through precise heat treatment cycles.

Evomatec provides state-of-the-art furnace technology and comprehensive know-how for heat treating all types of casting materials with accuracy and repeatability.

Stress Relief Annealing of Castings – Dimensional Stability Without Deformation

During stress relief annealing, cast parts are heated to temperatures between 500 °C and 650 °C to relieve internal stresses created during solidification and cooling.

Evomatec employs computer-controlled furnaces with exact temperature management, ensuring uniform heating and cooling.

Advantages:

-

No deformation during subsequent machining

-

Improved dimensional stability

-

Extended component lifetime

-

Prevention of cracking during heat treatment

Normalizing of Cast Iron – Uniform Grain Structure for Consistent Quality

Normalization dissolves and reforms the microstructure of cast iron through controlled heating and slow cooling.

Evomatec optimizes this process via digitally managed annealing cycles, achieving uniform microstructures with consistent strength and hardness.

Applications:

-

Gray cast iron housings with high wall thickness

-

Machine components requiring stability

-

Precision elements with tight tolerances

The result is a stable and uniform cast structure resistant to mechanical fatigue and stress deformation.

Tempering of Steel Castings – Balancing Strength and Toughness

Tempering is a multi-step process combining hardening and annealing.

The steel casting is first heated to austenitizing temperatures (800–950 °C), then quenched, followed by controlled reheating to achieve the desired toughness.

Evomatec applies precise temperature profiles and sensor-controlled cooling rates to guide the transformation of the microstructure.

Results:

-

Optimal balance between hardness and ductility

-

High impact resistance and fatigue strength

-

Improved mechanical reliability for critical components

Hardening of Cast Materials – Maximum Surface Resistance

The hardening of cast materials aims to enhance surface wear resistance while maintaining a tough, ductile core.

Evomatec employs induction and furnace hardening technologies precisely matched to each alloy composition.

Typical Applications:

-

Gears, crankshafts, camshafts

-

Valve housings and hydraulic components

-

Tools and mold inserts

Through controlled heating and cooling, Evomatec achieves reproducible hardness levels for all casting materials — from gray iron to steel castings.

Tempering of Castings – Controlled Stress Reduction

After hardening, tempering is used to relieve internal stresses and stabilize the microstructure.

Evomatec’s computer-controlled tempering systems execute multi-level temperature programs to achieve the desired material properties.

Results:

-

Enhanced toughness and elasticity

-

Controlled hardness retention

-

Dimensional and structural stability

Heat Treatment of Gray Cast Iron – Classic Stability with Modern Precision

Gray cast iron remains a fundamental industrial material.

Evomatec’s heat treatment processes include normalizing, stress relief annealing, and surface hardening, adapted to specific alloy compositions.

Advantages:

-

Reduction of internal stresses

-

Improved machinability and damping properties

-

Enhanced dimensional accuracy and durability

Using advanced furnace technology, Evomatec ensures stable microstructures and consistent mechanical performance for gray cast iron.

Heat Treatment of Ductile Iron – Optimizing the Spheroidal Graphite Structure

Ductile iron (GJS) contains spherical graphite structures that can be precisely modified through thermal treatment.

Evomatec’s temperature-controlled systems balance the ferrite-to-pearlite ratio for maximum performance.

Results:

-

High tensile strength with excellent ductility

-

Homogeneous structure without porosity

-

Improved machinability and stability

This makes Evomatec’s treatment ideal for automotive and mechanical engineering applications requiring high-strength components.

Heat Treatment of Steel Castings – Maximum Performance Under Extreme Loads

Steel castings are often used in high-stress environments.

Evomatec’s processes — tempering, normalizing, and stress relief annealing — are precisely adapted to material and application.

Advantages:

-

Increased tensile strength and fatigue resistance

-

Reduced brittleness and improved toughness

-

Reproducible mechanical properties through digital monitoring

Evomatec’s pyrometric and digital control systems ensure perfect temperature accuracy throughout heating and cooling cycles.

Heat Treatment of Aluminum Castings – Lightweight Precision Engineering

Aluminum castings benefit greatly from solution heat treatment and aging (T6 process), which significantly enhances their mechanical properties.

Evomatec Processes for Aluminum Casting:

-

Homogenization of the grain structure

-

Increased yield strength and ductility

-

Enhanced elongation and surface integrity

-

Precise thermal management for optimal consistency

These treatments produce lightweight yet strong aluminum castings for automotive bodies, aerospace structures, and machinery housings.

Microstructure and Phase Transformation – Precision at the Micron Level

The microstructure of a casting after heat treatment defines its strength, performance, and durability.

Evomatec utilizes metallography, scanning electron microscopy (SEM), and spectral analysis for in-depth monitoring and documentation.

Key Microstructural Transformations:

-

Pearlite to ferrite during normalization

-

Martensite formation during hardening

-

Bainitic structures during tempering

-

Controlled spheroidal graphite in ductile iron

This microstructural precision ensures long-term casting stability and quality consistency.

Furnace Technology and Heat Treatment Systems by Evomatec

Evomatec designs and manufactures industrial furnaces for all major casting materials:

-

Aluminum castings

-

Gray cast iron

-

Steel castings

-

Ductile iron

System Features:

-

Multi-zone gas furnaces with uniform heat distribution

-

Electric furnaces with precise temperature control

-

Vacuum and protective gas furnaces for specialized alloys

-

Automated batch management and process recording

The integration of furnace systems, temperature management, and model making establishes Evomatec as a complete provider of thermally optimized casting technology.

Industrial Applications – Heat Treatment for Every Foundry Sector

Evomatec delivers solutions for all foundry sectors, including:

-

Mechanical Engineering: Stress-relieved cast iron for machine bases

-

Automotive Industry: Tempered steel castings for drivetrains

-

Energy Systems: Heat-treated turbine components

-

Aerospace: Aged aluminum castings for structural parts

-

Toolmaking: Hardened molds and die components

In every application, casting quality, reproducibility, and documentation remain central to Evomatec’s commitment to excellence.

Research, Development, and Quality Assurance

Evomatec continuously invests in R&D focused on the heat treatment of casting materials.

Collaborations with universities and material laboratories enable the creation of new techniques that improve microstructure, energy efficiency, and process safety.

Quality Assurance Systems:

-

ISO-certified inspection procedures

-

Thermographic process monitoring

-

Real-time temperature tracking

-

Full documentation according to Industry 4.0 standards

These quality measures secure Evomatec’s leading position in the modern foundry industry.

Conclusion – Precision in Model Making and Excellence in Heat Treatment

Foundry model making with Sträfor by Evomatec embodies technical perfection and thermal precision.

By combining lightweight model construction, digital process control, and advanced heat treatment systems, Evomatec produces castings with maximum dimensional accuracy, strength, and structural stability.

Evomatec unites all key aspects of modern casting:

-

Precision-engineered models

-

Optimized heat treatment cycles

-

Controlled microstructures

-

Certified process reliability

-

Superior casting quality in every production run

Contact our sales team: info@evomatec.de

English

English German

German