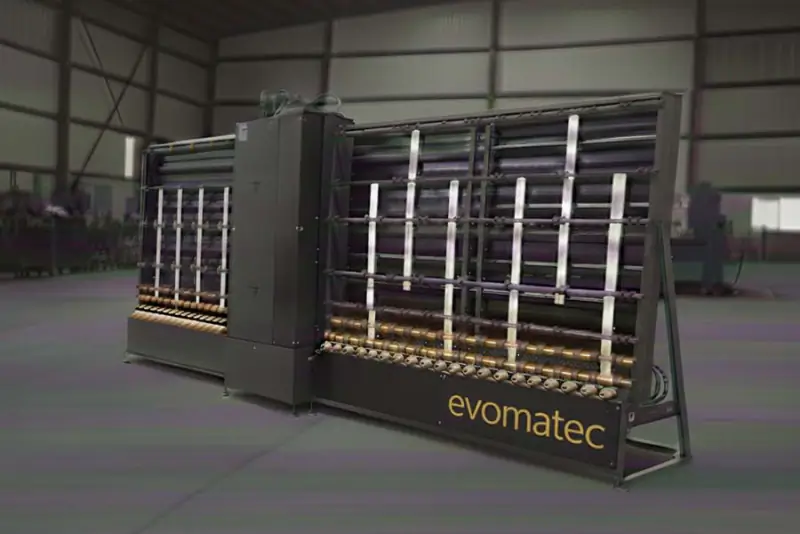

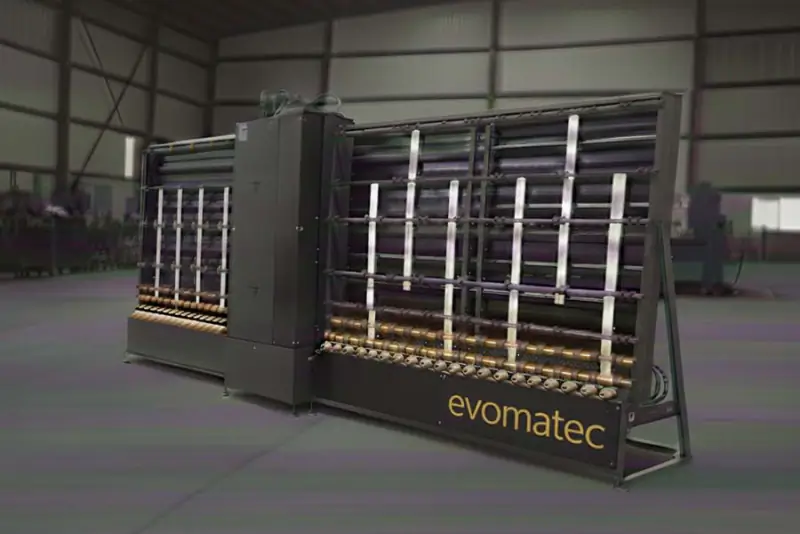

VERTICAL GLASS WASHING MACHINE EVOGLAS 1700 PLUS

Vertical Glass Washing Machine EVOGLAS 1700 PLUS – Precision Glass Cleaning at Industrial Level

High-Performance Glass Washing Machine for Flat, Insulating, and Architectural Glass

The vertical glass washing machine EVOGLAS 1700 PLUS by EVOMATEC is a fully automatic, industrially engineered high-performance system designed for washing and drying flat glass, insulating glass, and architectural glass.

It combines German engineering, a robust steel frame structure, and energy-efficient control technology in a compact and powerful machine.

The EVOGLAS series was developed specifically for glass manufacturers demanding the highest cleaning quality, efficiency, and durability — whether in insulating glass production, façade fabrication, or decorative and furniture glass finishing.

Thanks to its stable construction, stainless steel washing chamber, and maintenance-friendly design, it guarantees consistently high-quality cleaning results, even for sensitive surfaces such as coated or Low-E glass.

Technical Features of the EVOMATEC EVOGLAS Series

Precision, Stability, and Energy Efficiency

Working widths: 1300 mm – 2500 mm

Processable glass thickness: 3 mm – 10 mm

Glass size range: Min. 170 × 350 mm / Max. 2500 × 3210 mm

Conveyor speed: Infinitely variable from 3 to 10 m/min

Operating voltage: 380 V / 3 Phases / 50 Hz

Power consumption: 12 – 21 kW (depending on model)

Machine weight: 1000 – 1750 kg

These specifications make the EVOGLAS 1700 PLUS one of the most powerful vertical glass washing machines in its class — designed for continuous serial production in multi-shift industrial environments.

Construction and Design

Stainless Steel Durability and Industrial Strength

Stainless steel washing chamber (AISI 304): Ensures corrosion resistance, hygiene, and long service life

Heavy-duty steel frame structure: Welded support frame for vibration-free continuous operation

Brush system: 4–6 precision-balanced brush rollers ensure uniform cleaning of delicate glass surfaces

Wiper blades and transition brushes: Effectively remove water between washing zones

EPDM and polyurethane guides: Guarantee smooth glass transport with minimal vibration

Selectable washingection: Left or right, adaptable to production line layout

Warm water washing system: Efficiently removes oil, dust, and mineral residues

Sound-insulated drying unit: Delivers streak-free, clean surfaces through temperature-controlled airflow

Automatic water supply: Float valve maintains constant water level

Powder-coated housing: Protection against rust, oxidation, and chemicals

CE-compliant electrical installation: Meets all European safety and quality standards

High-Quality Industrial Components

Premium European Brand Technology

EVOMATEC uses top-tier European components to ensure maximum durability, precision, and operational safety:

Lenze (Germany): Frequency inverters and drive systems for precise brush motion

Schneider Electric (Germany): Electronic control, power distribution, and protection systems

Pepperl + Fuchs (Germany): Sensors for precise glass detection and process monitoring

These trusted components guarantee long-term reliability, minimal downtime, and stable production performance in demanding environments.

Operation and Control

Automated Precision Cleaning

The EVOGLAS 1700 PLUS operates via fully automatic PLC control with an intuitive touch panel interface.

All relevant parameters — brush speed, water temperature, conveyor speed, air pressure, and drying intensity — can be individually adjusted and stored for repeated production runs.

Variable conveyor control: Adjustable to glass thickness and contamination level

Zoned cleaning system: Separate washing, rinsing, and drying zones for optimal results

Energy-efficient pumps and fans: Low power consumption with high cleaning performance

Automatic water filtration and circulation: Conserves resources and reduces maintenance requirements

Temperature-controlled drying system: Provides streak-free results without thermal stress on glass

Safety monitoring system: Real-time sensor feedback with automatic shutdown in case of malfunction

Optional Equipment

To enhance flexibility and adapt to various production needs, the EVOGLAS 1700 PLUS can be equipped with multiple options:

Pre-washing unit with separate filtration system – for heavily soiled glass

Automatic glass thickness detection – with adaptive brush pressure control

Energy-saving heating elements – for warm water operation with reduced power usage

Advanced PLC software programs – for customized production sequences

Air filtration system in drying section – ensures dust-free, flawless glass finish

Integration with insulating glass lines – synchronized glass transport for continuous production

Advantages of the EVOMATEC EVOGLAS 1700 PLUS

Superior Cleaning Quality

Delivers spotless results even for delicate glass types — from float glass to Low-E and tinted glass.Energy-Efficient Technology

Modern pumps, variable-frequency drives, and heat recovery systems reduce energy consumption and operating costs.Robust Industrial Design

Heavy-duty steel and stainless-steel components ensure strength and longevity in 24/7 industrial operations.Maintenance-Friendly Construction

Filters, brushes, and nozzles are easily accessible, minimizing downtime and simplifying maintenance.Flexible Integration

Seamlessly connects to any production line — ideal for insulating glass, window, and glass finishing plants.Certified Safety and Compliance

Fully CE-certified with intelligent fault diagnosis and automatic protective shutdown for maximum operational safety.

Application Areas

The EVOGLAS 1700 PLUS is suitable for a wide range of industrial glass processing applications:

Insulating and laminated glass production

Architectural and façade glass fabrication

Interior and furniture glass manufacturing

Window and door production (aluminum / PVC)

Specialty and decorative glass processing

Whether used as a stand-alone unit or integrated module in a complete line, the EVOGLAS series ensures maximum precision, energy efficiency, and process stability for modern glass manufacturers.

Conclusion

The vertical glass washing machine EVOGLAS 1700 PLUS by EVOMATEC embodies industrial-grade quality, German precision, and long-lasting efficiency.

With advanced automation technology, energy-optimized systems, and premium construction, it provides a future-proof solution for glass factories of all sizes.

Whether for insulating glass, architectural glass, or furniture applications, the EVOGLAS 1700 PLUS guarantees brilliant cleaning performance, quiet operation, and low operating costs.

EVOMATEC EVOGLAS – Engineering for Precision.

Contact us for personal consultation: Click Here

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi