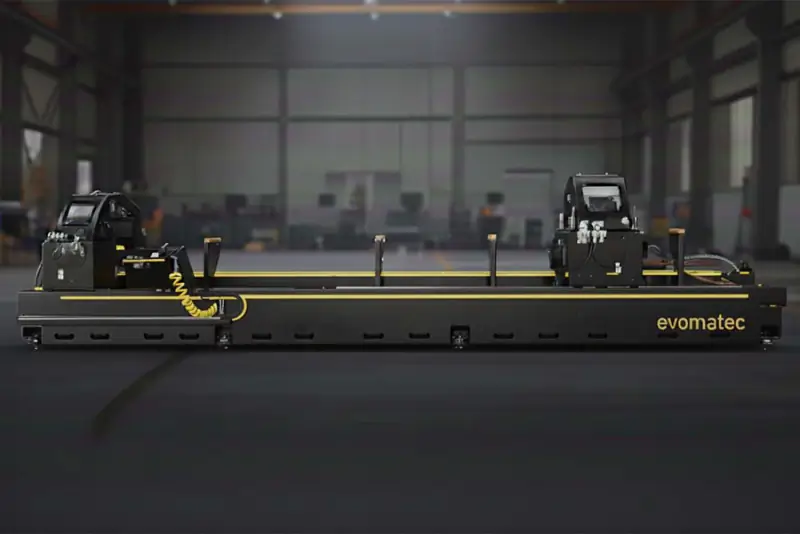

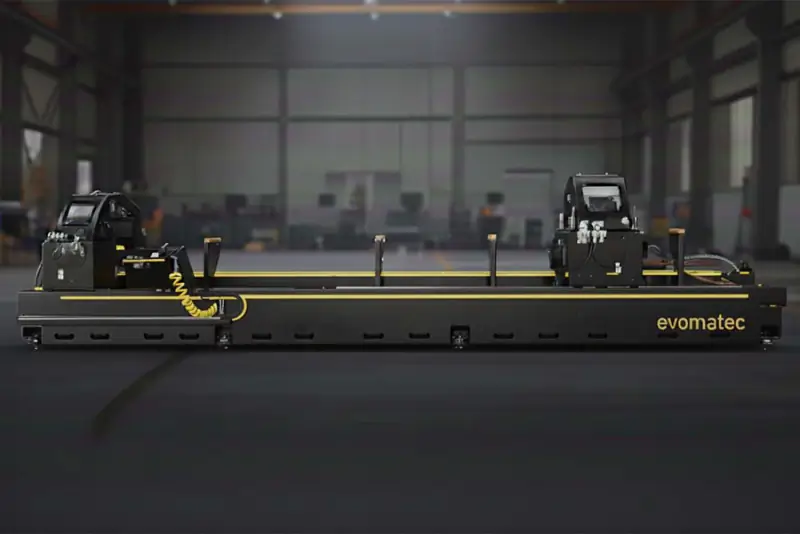

AUTOMATIC DOUBLE MITRE SAW EVOG X

Automatic Double Mitre Saw EVOG X – Precision and Speed for PVC, Plastic, and Window Profiles

Industrial Standard for Accurate Mitre Cuts

Why Mitre Precision Matters in PVC Window Manufacturing

In PVC window construction, fit accuracy, tightness and surface quality define the final product. The EVOG X combines servo-technology with digital angle control so that frame and sash profiles are delivered burr-free and dimensionally accurate — ready for welding and corner-finishing.

Key Technical Highlights

Saw blades: 2 × Ø 550 mm, carbide-tipped

Motor power: 2 × 3 kW (4 HP)

Cutting lengths: 460–6,000 mm

Angle adjustment: servo-controlled 30°–90°

Feed: hydro-pneumatically regulated

Positioning speed: 40 m/min

Air requirement: 6–8 bar (~150 L/min)

Total power: 9.1 kW | 400 V | 50–60 Hz

Machine weight: approx. 2,240 kg

Equipment – Productive, Safe, Digital

Standard Features

Automatic head positioning with digital angle control (30° / 45° / 90° & intermediate angles)

Pneumatic clamping cylinders (horizontal/vertical)

Spray-cooling system for PVC and plastic profiles

Heavy-duty roller table for long profiles

Electronic feed & cut speed controls

CE-compliant safety hoods and emergency stop

10″ touchscreen, Ethernet/USB interfaces

Interface for chip extraction

Optional Features

EVOSOFT cut-optimization (waste reduction, job administration)

Barcode printer for production traceability

Supports for extra-long profiles

Automatic chip/dust extraction with filter system

Performance Features That Count

1) Precision & Repeatability

Servo driven head axes deliver helical accuracy in tenths of a millimetre — ideal for PVC profiles, window frames and sash components in large scale series.

2) High Capacity up to 6 m

With a cutting length of 6,000 mm, the EVOG X is well suited for door profiles, façade systems and large frame sections.

3) Clean Cuts Without Rework

Hydro-pneumatic feed plus spray cooling prevents material heating and deformation — resulting in smooth, burr-free mitres ready for immediate processing.

4) Robust, Low-Maintenance Design

A massive cast machine bed, precision guides and encapsulated drives ensure a long service life and minimal maintenance.

5) Simple, Fast Operation

Via the 10″ touchscreen, angles, positions and feed settings are pre-selected, stored and recalled — ideal for automated production lines.

6) Safety & Efficiency

CE-certified enclosure protects operators; servo drives engage on demand to reduce energy usage and increase component lifetime.

Typical Applications

Window manufacturing: Mitre cutting for frame and sash profiles

Door production: Accurate 45° / 90° cuts for plastic door frames

Façade systems: Dimensional cuts for PVC or hybrid profiles

Profile processing: Suitable for PVC, ABS, PMMA, polycarbonate and more

Process Flow – From Profile to Perfect Mitre

Automatic positioning & pneumatic clamping of the profile

Servo angle adjustment of both saw heads to target angles

Hydro-pneumatic feed produces a steady, controlled cut

Spray cooling prevents edge melting and ensures sleek cut surfaces

Data capture via Ethernet/USB; automatic return initiates the next cycle

Quality, Safety & Future-readiness

Each EVOG X is CE-compliant, electrically and mechanically tested, and mechanically calibrated. With Industry 4.0 interfaces, cut-optimization software and barcode integration, it is ready for digitally networked manufacturing — and comes with global service and spare-parts support.

Conclusion – Precision At The Push of a Button

The Automatic Double Mitre Saw EVOG X merges servo precision, digital control and hydro-pneumatic cutting quality. For operations that demand high volume, exact angles and industrial durability, the EVOG X is the state-of-the-art solution for PVC, plastic and window profile cutting.

Contact our team for a free consultation: Click here

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi