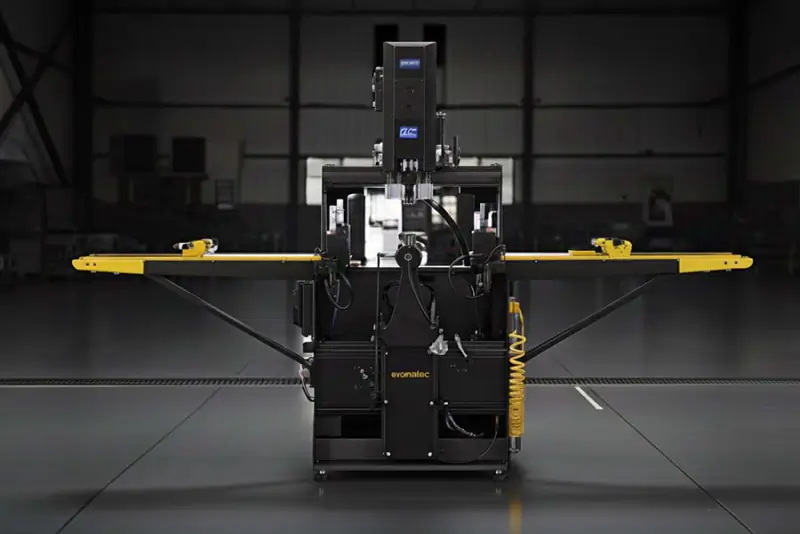

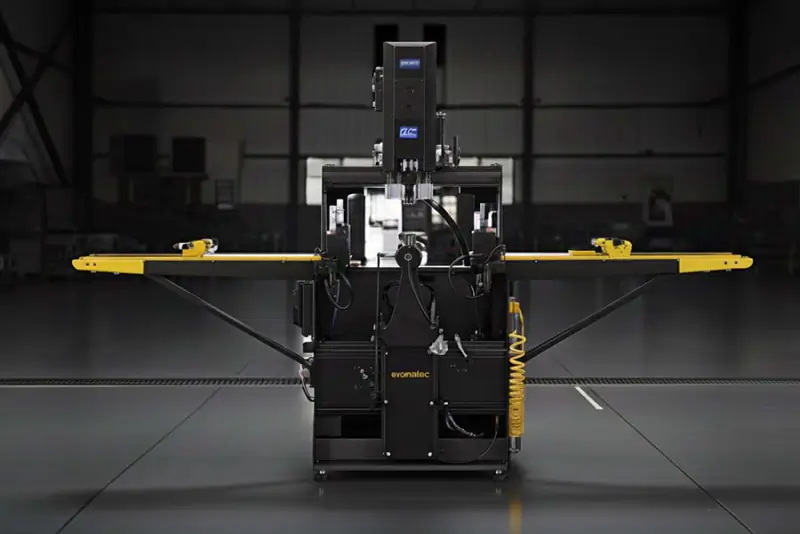

ALUMINIUM PROFILE COPY ROUTER WITH 3 SPINDLES EVOG IV

ALUMINIUM PROFILE COPY ROUTER WITH 3 SPINDLES – EVOG IV

Simultaneous Multi-Side Milling for Maximum Precision and Industrial Efficiency

High-Performance Copy Router for Aluminium Profiles – Triple-Spindle Technology for Three-Side Machining

The EVOG IV Aluminium Profile Copy Router with 3 Spindles is an advanced industrial milling machine designed for simultaneous three-side processing of aluminium profiles.

Equipped with three independent high-speed spindle motors, it enables concurrent machining of lock slots, handle holes, hinge recesses, and locking channels with exceptional precision and consistency.

Its robust cast-iron frame, pneumatic clamping system, and integrated cooling ensure perfect dimensional accuracy, burr-free surfaces, and minimal setup times.

This makes the EVOG IV the ideal solution for high-volume aluminium profile manufacturing in window, door, and façade production.

Precision and Productivity in Aluminium Profile Machining

The EVOG IV Copy Router with 3 Spindles drastically reduces machining time by allowing simultaneous milling on three surfaces of a profile.

Each spindle operates independently, offering adjustable depth control and feed rate settings for each working side.

Whether for lock slots, handle openings, hinge grooves, or locking channels, this advanced router delivers clean, accurate, and repeatable results with minimal finishing effort.

Manufacturers benefit from high throughput, maximum precision, and superior process reliability, even under demanding production conditions.

Innovative Three-Spindle Milling System with Precision Control

Triple-Synchronized Spindle Operation

Three independent spindle motors work simultaneously on the front, top, and rear surfaces of the profile — enabling complete machining in one cycle.

Pneumatic Clamping System

Securely fixes the profile during the entire milling process, ensuring vibration-free, high-precision operation.

High-Precision Guide Rails

Guarantee smooth linear movement and stable positioning for all spindle units.

Integrated Cooling System

Prevents overheating, ensures burr-free surface quality, and significantly extends tool lifespan.

Adjustable Milling Depth

Each spindle allows independent adjustment for customized depth and feed — perfect for complex aluminium profile geometries.

This combination of mechanical rigidity, synchronized spindle control, and automated cooling ensures top performance even in continuous industrial production.

Technical Specifications

Spindle Motors: 3 × 1.5 HP (1.1 kW each)

Speed: 12,000 rpm per spindle

Power Supply: 230 V / 50–60 Hz

Cutter Diameter: 8 mm (standard), optional 5–10 mm

Working Travel:

X1: 460 mm | Y1: 210 mm | Z1: 210 mm

X2: 430 mm | Y2: 240 mm | Z2: 145 mm

Air Pressure: 6–8 bar | Air Consumption: 9 L/min

Machine Dimensions: 2,815 × 1,430 × 1,835 mm

Machine Weight: 293 kg

Cooling System: integrated

Clamping System: pneumatic, CE-certified

Advantages of the EVOG IV Aluminium Profile Copy Router with 3 Spindles

Simultaneous Three-Side Machining

Front, top, and rear surfaces are milled in a single pass — reducing cycle times dramatically.

Unmatched Precision and Repeatability

Independent spindle control ensures consistent dimensional accuracy even for long or complex profiles.

High Productivity and Process Efficiency

Triple-spindle technology cuts total machining time while maintaining premium surface quality.

Vibration-Free Operation

Heavy-duty frame construction minimizes vibration, improving tool life and finish quality.

Adjustable Milling Depth

Independent spindle depth control for flexible adaptation to various profile cross-sections.

Energy Efficiency and Low Maintenance

Optimized pneumatic and cooling systems minimize air consumption and ensure long-lasting reliability.

CE-Certified Safety

Complies with all European industrial safety and CE standards.

Typical Applications

Window Production

Machining of lock slots, handle holes, hinge recesses, and drainage channels in aluminium sash and frame profiles.

Door Manufacturing

Precise milling of lock housings, handle recesses, and latch systems.

Façade Construction

Accurate processing of connector slots, screw channels, and mounting apertures.

Metal and Light Alloy Processing

Simultaneous multi-surface machining of aluminium and hybrid profiles for industrial applications.

Custom Profile Fabrication

Adjustable spindle configurations and copy systems for specialized and complex profile geometries.

Economic Efficiency and Industrial Reliability

The EVOG IV Aluminium Profile Copy Router with 3 Spindles offers a perfect balance of productivity, precision, and energy efficiency.

By machining three surfaces at once, it reduces cycle times, minimizes operator workload, and ensures consistent surface quality.

The low-maintenance design, integrated cooling, and robust pneumatic clamping system guarantee long-term reliability in continuous operation.

Manufacturers benefit from reduced downtime, stable process control, and maximum return on investment — making the EVOG IV a strategic asset in modern production lines.

Conclusion

The EVOG IV Aluminium Profile Copy Router with 3 Spindles represents the peak of industrial innovation in multi-surface profile machining.

With its three synchronized spindles, adjustable depth control, and precision clamping technology, it provides a high-performance all-in-one milling system for professional use.

Whether in window, door, or façade production, the EVOG IV ensures maximum speed, precision, and cost-efficiency, setting new standards in aluminium profile manufacturing.

EVOMATEC – Machinery for Precision Aluminium Profile Processing

For technical consultation and quotations: info@evomatec.de

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi