AUTOMATIC DOUBLE MITRE SAW FOR ALUMINIUM PROFILES EVOG VR

AUTOMATIC DOUBLE MITRE SAW FOR ALUMINIUM PROFILES - EVOG VR

Servo-Controlled Precision, Maximum Efficiency and Fully Automatic Angle Control for Aluminium Profiles

Highest Precision and Productivity in Aluminium Profile Processing

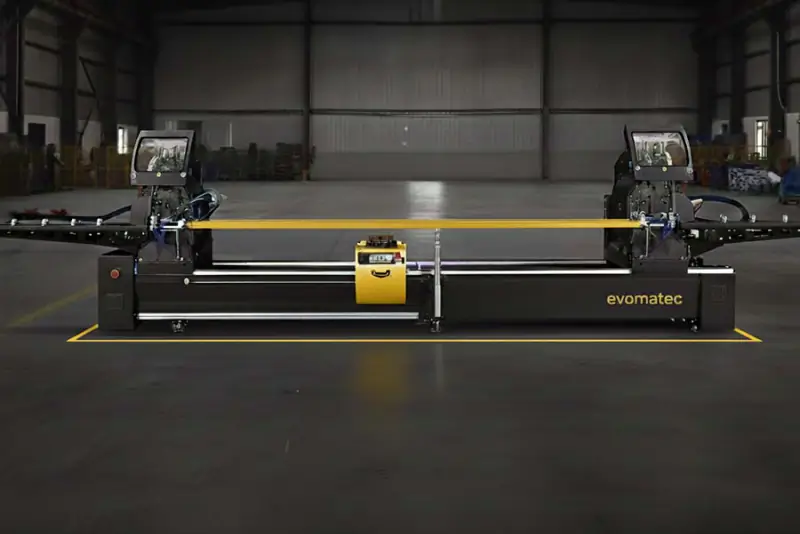

The EVOG VR Automatic Double Mitre Saw for aluminium profiles by EVOMATEC is a high-performance industrial machine designed for the accurate mitre cutting of aluminium profile ends.

Featuring advanced 3-axis servo technology, hydro-pneumatic feed control, and fully automatic angle adjustment, it guarantees maximum precision, repeatability, and productivity — even under demanding serial production conditions.

The EVOG VR is the ideal solution for window, door, and façade manufacturing, where precise angles, smooth cutting surfaces, and consistent results are essential.

With an adjustable angle range from –22.5° to +45° and servo-controlled head positioning, it offers complete automation and flexibility for a variety of aluminium profiles — efficient, safe, and fully CE-compliant.

Servo Technology for Precise, Fully Automated Mitre Cutting

Intelligent CNC System for Absolute Accuracy

The EVOG VR Double Mitre Saw combines digital servo control, robust mechanical construction, and intelligent hydraulic systems.

Its 3-axis servo technology enables fully automatic head positioning and precise angle adjustment between –22.5° and +45° — ideal for frame joints, façade profiles, and complex cutting geometries.

The hydro-pneumatic feed system ensures smooth, vibration-free operation, while the digital feed and speed control guarantee dimensional stability and burr-free results at every cycle.

Technical Specifications of the EVOG VR Automatic Double Mitre Saw

| Technical Specification | Value |

|---|---|

| Saw Blades | 2 × Ø 550 mm, carbide-tipped (HM) |

| Motor Power | 2 × 3 kW / 4 HP |

| Cutting Length | 480 mm – 5,050 mm |

| Cutting Angle | Servo-controlled between –22.5° and +45° |

| Cutting Feed | Hydro-pneumatically regulated |

| Positioning Speed | 40 m/min |

| Air Pressure / Consumption | 6 – 8 bar / 70 L/min |

| Total Power | 9.1 kW |

| Machine Weight | approx. 1,490 kg |

| Safety Standard | CE-certified according to EU Directive 2006/42/EC |

Standard Equipment

-

Two Ø 550 mm carbide-tipped saw blades

-

Automatic servo angle adjustment (3-axis system)

-

Pneumatic clamping cylinders (horizontal & vertical)

-

Hydro-pneumatic feed control for steady cutting motion

-

Spray cooling system for clean, burr-free edges

-

Movable roller conveyor with servo positioning

-

10″ touchscreen control panel with intuitive interface

-

Digital feed and speed control

-

CE-certified safety enclosure and emergency stop system

-

Connection port for chip extraction

Optional Equipment

-

EVOSOFT optimisation software for automatic cut sequence calculation

-

Barcode printer for production integration and traceability

-

Ethernet / USB data transfer for ERP and factory software connection

-

Digital head position display

-

Additional profile supports for long workpieces

-

Automatic chip extraction for clean and low-maintenance operation

Advantages of the EVOG VR Automatic Double Mitre Saw

1. Servo-Controlled Precision

Fully automated servo drives ensure millimetre-perfect positioning and precise angle cutting, even with large profiles or complex geometries.

2. Flexible Angle Adjustment

The servo-controlled range from –22.5° to +45° provides maximum flexibility for windows, doors, façades, and custom fabrications.

3. Maximum Efficiency

With CNC automation, automatic head movement, and digital cut control, cycle times are reduced and overall production speed is increased.

4. Energy-Efficient and Low-Maintenance

The combination of hydro-pneumatic control, servo motors, and optimised electronics ensures low energy consumption and minimal maintenance costs.

5. CE-Certified Safety

Protective covers, interlocks, and emergency stop systems guarantee maximum operator safety according to EU machinery regulations.

Application Areas of the EVOG VR Double Mitre Saw

The EVOG VR Automatic Double Mitre Saw for aluminium profiles is suitable for a wide range of industrial applications:

-

Window manufacturing: precise mitre cuts for frame and sash profiles

-

Door production: exact 45° and 90° cuts for door frames and profiles

-

Façade construction: large-format profiles for load-bearing and connection systems

-

Metal fabrication: flexible processing of aluminium and PVC profiles

-

Industrial manufacturing: serial production of aluminium frames, covers, and structural systems

Its servo-driven automation, fast angle control, and digital CNC operation make it the ideal choice for automated production lines and industrial-scale series manufacturing.

Quality, Reliability and CE Compliance

Each EVOG VR is manufactured, calibrated, and tested under strict European quality standards.

Evomatec guarantees:

-

Precise servo calibration before shipment

-

100% functional testing and safety certification

-

Durable components and maintenance-friendly design

-

CE-compliant manufacturing according to EN 60204-1 and EN ISO 12100

This rigorous process ensures that every machine operates accurately, safely, and economically — day after day, shift after shift.

Conclusion – Precision, Efficiency and Automation in Perfection

The EVOG VR Automatic Double Mitre Saw for aluminium profiles represents technological excellence, servo-controlled precision, and industrial reliability.

With fully automated 3-axis control, hydro-pneumatic feed regulation, and digital CNC interface, it delivers the perfect combination of cutting quality, speed, and energy efficiency.

It is the ideal solution for manufacturers who require precise, economical, and CE-compliant mitre cutting in aluminium profile production.

EVOMATEC – Machines for Precise Aluminium Profile Processing

Contact: info@evomatec.de

Free Consultation: Click Here

English

English German

German