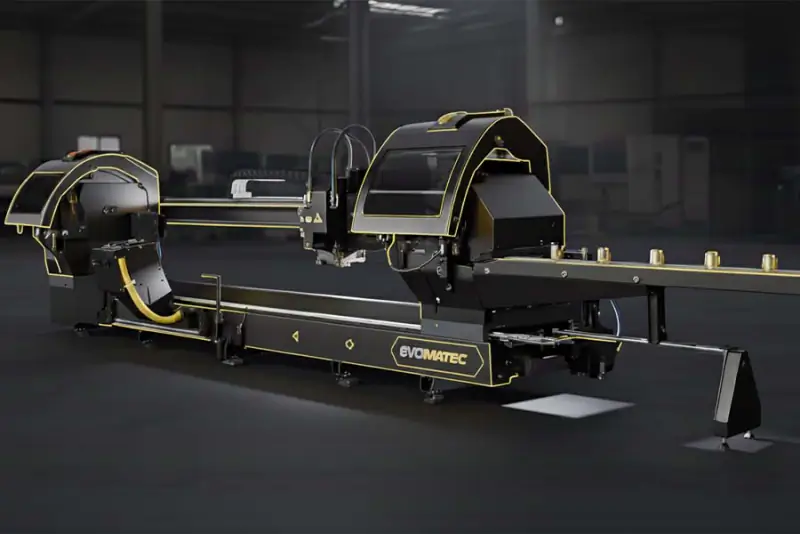

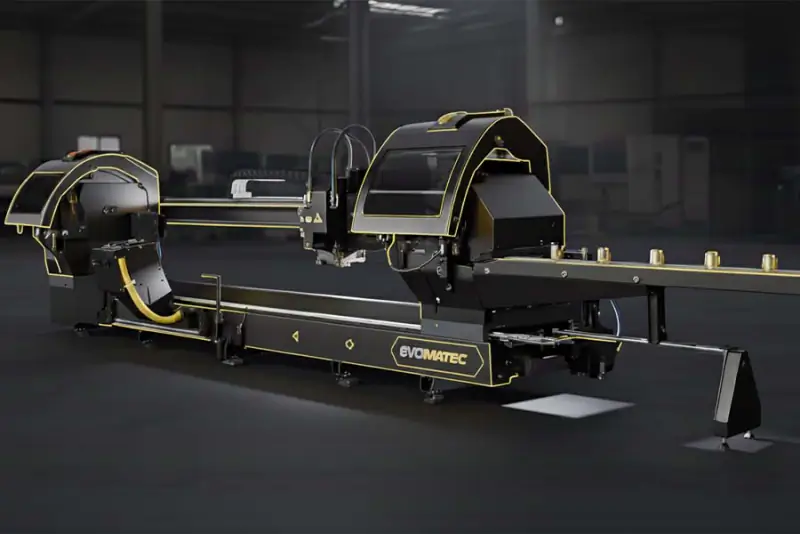

AUTOMATIC DOUBLE MITRE SAW FOR ALUMINIUM PROFILES EVOG VI

AUTOMATIC DOUBLE MITRE SAW FOR ALUMINIUM PROFILES – EVOG VI

Precise, Automated Mitre Cuts for Aluminium Profiles

Advanced CNC Cutting Technology for Maximum Precision and Productivity

The EVOG VI Automatic Double Mitre Saw for aluminium profiles by EVOMATEC is designed to deliver ultimate precision, productivity, and flexibility in aluminium profile processing.

Equipped with servo-controlled 3-axis technology, automatic angle positioning, and Ø 600 mm carbide-tipped saw blades, it ensures millimetre-accurate, burr-free cuts — perfectly suited for the demands of window, door, and façade manufacturing.

Combining digital CNC control, hydro-pneumatic feed systems, and a robust cast-iron frame, the EVOG VI delivers stable, vibration-free operation, long service life, and exceptional energy efficiency — ideal for continuous industrial use.

Servo Technology for Maximum Precision

Fully Automated Dual-Head Control for Perfect Angle Cuts

The EVOG VI employs cutting-edge servo technology for fully automatic control of both cutting heads.

Each head can be positioned precisely within an angle range of –22.5° to +45°, with full servo-driven accuracy and digital feedback monitoring.

This ensures exact angle positioning, flawless dimensional consistency, and clean, burr-free edges, even when cutting large aluminium profiles or complex cross-sections.

Technical Specifications of the EVOG VI Double Mitre Saw

| Technical Specification | Value |

|---|---|

| Saw Blades | 2 × Ø 600 mm carbide-tipped (HM) |

| Motor Power | 2 × 3 kW (4 HP) |

| Cutting Length | 480 mm – 5,050 mm |

| Angle Range | Servo-controlled from –22.5° to +45° |

| Feed System | Hydro-pneumatically regulated |

| Positioning Speed | 40 m/min |

| Air Pressure / Consumption | 6–8 bar / 95 L/min |

| Total Power | 9.1 kW |

| Machine Weight | approx. 1,530 kg |

| Safety Standard | CE-certified according to EU Machineryective 2006/42/EC |

Standard Equipment

Two Ø 600 mm carbide-tipped saw blades

Servo-controlled dual heads with automatic angle positioning

Pneumatic clamping systems (horizontal and vertical)

Hydro-pneumatic feed regulation for smooth, precise cutting motion

Spray mist cooling system for aluminium profiles

Roller table on movable head for long profiles

Electronic control for feed and cutting speed

10″ touchscreen control panel with digital display

Enclosed safety covers and CE-certified protection systems

Compatible with central chip extraction units

Optional Equipment

EVOSOFT Cutting Optimisation Software: automatically calculates the optimal cutting sequence for material savings

Barcode Printer: integration into production lines and traceability systems

Ethernet / USB Interfaces: data transfer to ERP and manufacturing software

Additional Intermediate Supports: for long or heavy profiles

Automatic Chip Extraction System: ensures a clean workspace and extends tool life

Advantages of the EVOG VI Double Mitre Saw

1. Ultimate Precision Through Servo Technology

Servo-controlled cutting heads ensure exact, repeatable angle positioning — for perfect, burr-free cuts without rework.

2. Flexibility for All Profile Geometries

With a cutting range from 480 to 5,050 mm and an angle range from –22.5° to +45°, the EVOG VI handles all window, door, and façade profiles with ease.

3. Long-Lasting Industrial Quality

The solid machine bed and premium industrial components provide vibration-free cuts and extended service life, even in multi-shift production.

4. Energy Efficiency and Safety

CE-certified safety systems, modern motor control, and energy-optimised pneumatics ensure reliable, efficient, and safe operation.

5. Productivity Through Automation

Servo technology, digital control, and the optional EVOSOFT optimisation system reduce cycle times, minimise material waste, and maximise production performance.

Application Areas

The EVOG VI Automatic Double Mitre Saw for aluminium profiles is versatile and ideal for a wide range of applications:

Window manufacturing: precise mitre cuts for frame and sash profiles

Door production: accurate cuts for durable aluminium door frames

Façade construction: processing of large structural aluminium profiles

Metal and industrial construction: cutting of aluminium, PVC, and light alloys

Serial production: high-volume manufacturing with consistent quality

Thanks to its automatic servo control and digital cutting optimisation, the EVOG VI is the perfect solution for both industrial line production and precise individual manufacturing.

Quality, Safety and CE Compliance

Each EVOG VI is manufactured and tested in accordance with strict European quality standards:

Full servo-axis calibration before delivery

Electrical and mechanical safety inspection according to EN 60204-1

Vibration and cutting precision testing

Final CE-certified acceptance test

The result is precise, safe, and long-lasting aluminium cutting technology, built to meet German industrial standards.

Efficiency and Investment Security

The EVOG VI increases production output, reduces material and energy consumption, and significantly lowers setup times.

Thanks to servo-driven automation and EVOSOFT integration, the machine offers a rapid return on investment — a true asset for any modern manufacturing facility.

Your benefits at a glance:

Shorter production cycles

Precise repeatability

Reduced waste and offcuts

Energy-efficient performance

Low maintenance requirements

Future-ready control architecture

Conclusion – Servo Precision and Industrial Efficiency Perfected

The EVOG VI Automatic Double Mitre Saw represents the pinnacle of servo technology, industrial productivity, and engineering reliability.

With fully automatic angle control, hydro-pneumatic feed regulation, and a durable construction, it offers maximum performance and longevity in aluminium profile processing.

For manufacturers seeking precision, efficiency, and safety, the EVOG VI is the ultimate choice — developed and built by EVOMATEC, the specialist in advanced aluminium profile machinery.

Contact: info@evomatec.de

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi